Polyvinyl Butyral Resin

Polyvinyl Butyral Resin Specification

- Type

- Polyvinyl Butyral Resin

- CAS No

- 63148-65-2

- EINECS No

- 203-253-7

- Grade

- Industrial Grade

- Purity(%)

- 99%

- Application

- Laminated Glass, Safety Glass, Automotive Glass, Architectural Glass

- Color

- White

- Form

- Powder

- Moisture Content

- 0.5%

- HS Code

- 39094000

- Viscosity

- 1200-2600 mPa.s (10% solution, 20C)

- Melting Point

- 170-180C

- Glass Transition Temperature (Tg)

- 57-62C

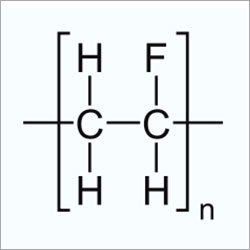

- Molecular Formula

- (C8H14O3)n

- Packing Type

- 25 kg Bag

- Storage Conditions

- Cool, Dry Place

- Shelf Life

- 24 Months

- Solubility

- Soluble in alcohols, insoluble in water

Polyvinyl Butyral Resin Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- Piece

- Delivery Time

- Days

- Sample Policy

- Contact us for information regarding our sample policy

About Polyvinyl Butyral Resin

We are reckoned among the trusted manufacturers, exporters and suppliers of impeccable quality Polyvinyl Butyral Resin, which is prepared by hydrolysis of Polyvinyl Acetate to form Polyvinyl Alcohol & later on it is acetalized to form Polyvinyl Butyral (PVB) Resin. The substance possess excellent binding properties and used to manufacture adhesives. The excellent adhesion binds surface with good strength. Polyvinyl Butyral Resin is used for secure bonding flexographic and gravure printing. We welcome the inquiries from our customers for bulk or urgent requirements.

Features:

- Excellent binding properties

- Used to manufacture adhesives

- Good strength

- At industry leading price

Industrial Versatility and Quality

Polyvinyl Butyral Resin stands out for its impressive versatility, making it an essential material in laminated, safety, automotive, and architectural glass. Its consistent powder form, 99% purity, and reliable adhesive properties guarantee strength and clarity in finished glass products. With a controlled molecular structure and moisture content kept below 0.5%, manufacturers can rely on its quality for demanding applications.

Optimal Storage and Handling

To preserve Polyvinyl Butyral Resins integrity, it must be stored in cool, dry environments. Delivered in convenient 25 kg bags, this packaging facilitates easy handling and measured use in industrial settings. Strict adherence to the specified storage conditions helps maintain its 24-month shelf life and ensures stable performance during processing.

FAQs of Polyvinyl Butyral Resin:

Q: How is Polyvinyl Butyral Resin commonly used in industry?

A: Polyvinyl Butyral Resin is primarily used as an interlayer in laminated glass, safety glass, automotive windshields, and architectural glazing. It enhances optical clarity, impact resistance, and safety by holding glass fragments together after breakage.Q: What storage conditions are recommended for optimal shelf life?

A: The resin should be stored in a cool, dry place, away from direct sunlight and moisture. These conditions help maintain its powder form, ensure less than 0.5% moisture content, and preserve its 24-month shelf life.Q: When should Polyvinyl Butyral Resin be processed to ensure best performance?

A: It is advisable to use and process the resin within 24 months from the manufacturing date, adhering to the recommended storage guidelines to prevent degradation and maintain optimal viscosity and purity.Q: Where can this Polyvinyl Butyral Resin be sourced in India?

A: This grade of PVB resin can be sourced from established exporters, manufacturers, and suppliers across India, who supply it in bulk quantities with compliance to international standards and proper documentation, including CAS No: 63148-65-2 and EINECS No: 203-253-7.Q: What is the process of incorporating PVB resin into laminated glass manufacturing?

A: The resin is first dissolved in appropriate alcohols to form a solution, cast or extruded into thin films, and then layered between glass sheets under heat and pressure. This process creates a durable laminate that enhances safety and sound insulation.Q: What benefits does Polyvinyl Butyral Resin provide in glass applications?

A: PVB resin delivers strong adhesion, high clarity, flexibility, and enhanced safety. Its properties help absorb impact, reduce noise, and provide UV protection, making it indispensable for advanced glass products.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Synthetic Resins Category

Liquid Resin

Price 200 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Flock printing & PVC Wood lamination

Type : Synthetic Resin

Grade : Industrial Grade

Color : Transparent

Butyral Resin

Price 100 INR

Minimum Order Quantity : 1 Piece

Application : Industrial Coating, Adhesives, Printing Ink, Paint

Type : Synthetic Resin

Grade : Industrial Grade

Color : White

PVF Resin

Application : Industrial Coatings, Films, Insulation, Chemical Resistance Linings

Type : Other, PVF Resin

Grade : Industrial Grade

Color : White Powder

Synthetic Resin

Application : Adhesives

Type : Synthetic Resin

Grade : Industrial Grade

Color : White

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry